25% LESS TIME, 25% COMPETITIVE PRICING

We crush the Robotics and Automation Competition in the US with our unique Workflow & Supply Chain

- 2yr ROI for 15+ customers

- 35 Projects Delivered Before Deadline in 2023

- Saved 100s of hours of downtime with our 24x7 support

Elite automation solutions

What our Customers Say About Us

ELITE DELIVERY & SUPPORT

We are convinced you guys don't sleep and we appreciate that. ~ Jon Harris, HC Companies

ELITE Automation Solutions

Elite always comes up with creative automation solutions for complex processes.

Elite Customers

Elite Automation Mission

At Elite Automation, we are driven by a mission to help businesses in the USA achieve greater profitability and efficiency while freeing up human potential. Our innovative automation and robotics solutions are designed to streamline processes and reduce the need for manual labor, enabling workers to focus on more meaningful tasks.

With cutting-edge technology and industry expertise, we empower our clients to take their operations to the next level.

Elite Automation Blog

Robotic Welding Cells: Key Design Factors for Precision

Robotic welding cells have become the cornerstone of modern manufacturing, delivering unmatched precision and efficiency. However, successful implementation hinges on meticulous design. In this blog post, we unravel the essential factors to consider when designing robotic welding cells, ensuring your operations are seamless and cost-effective.

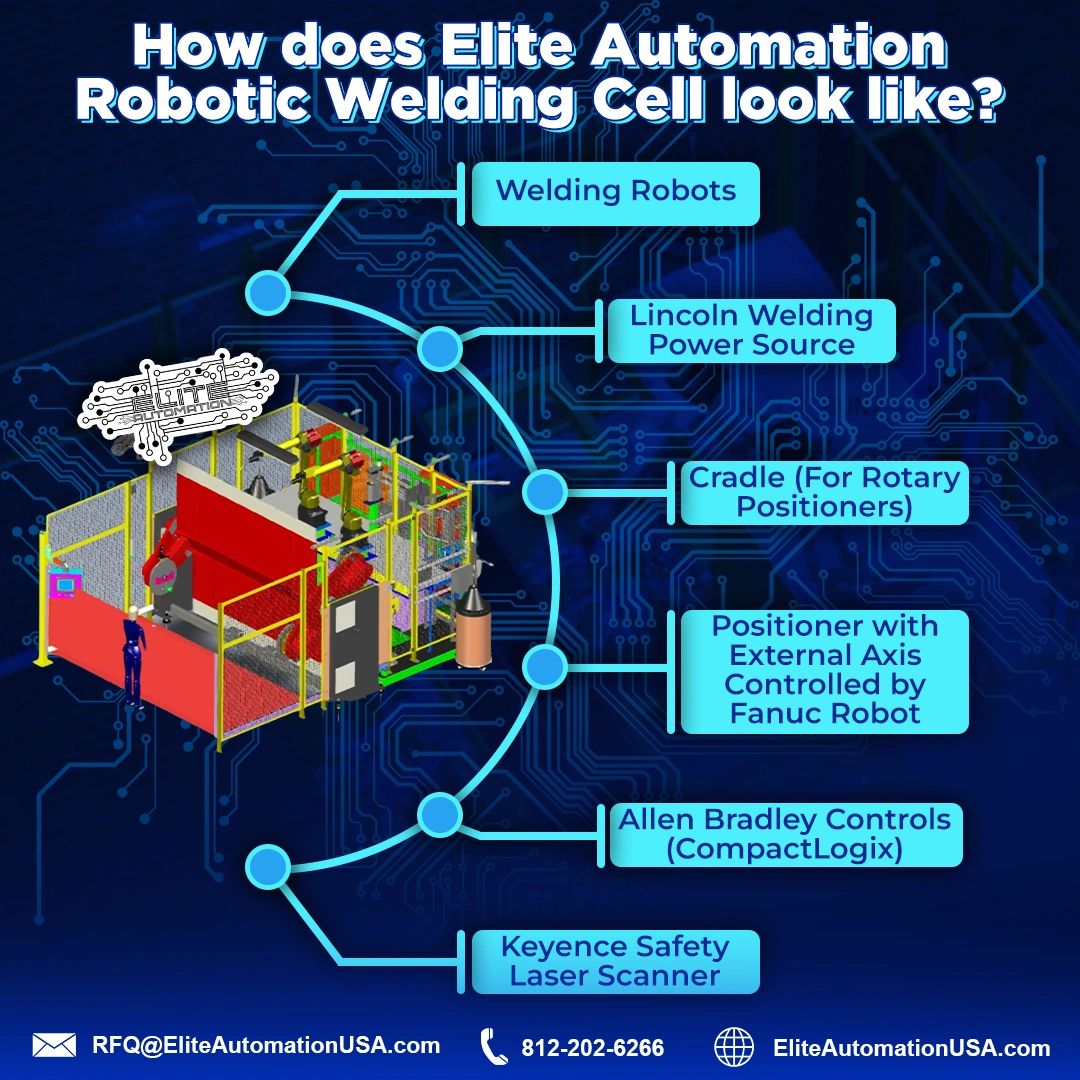

The Core Components of Robotic Welding Cells

Robotic welding cells consist of several components working in tandem:

- Robots: The heart of the system, robots execute welding tasks with unparalleled precision.

- Welding Equipment: Choosing the right welding machine and torch is crucial for weld quality.

- Workpiece Fixturing: Properly securing workpieces ensures consistent welds.

- Safety Measures: Implementing safety features is essential to protect human workers and equipment.

Key Factors in Designing Robotic Welding Cells

1. Workpiece and Material Considerations

Before diving into design, comprehensively understand your workpiece and material requirements. Factors to ponder include material type, thickness, and geometry. Precise workpiece measurements are crucial for proper fixture design and robot programming.

2. Welding Process Selection

Select the welding process (MIG, TIG, spot, etc.) that aligns with your application's demands. Each process has its own set of parameters, and the robotic welding cell design should accommodate these specifics.

3. Robot Selection and Placement

Choose the right robot for the job, considering payload capacity, reach, and repeatability. Optimal robot placement ensures maximum coverage and minimizes cycle times.

4. Fixture Design and Optimization

Workpiece fixturing is the backbone of consistent weld quality. Design fixtures that securely hold workpieces, allow easy loading and unloading, and minimize distortion during welding.

5. Safety Protocols and Integration

Safety is non-negotiable. Integrate safety features such as barriers, light curtains, and emergency stops to protect human workers. Collaborative robots may be a viable option for scenarios where human-robot interaction is necessary.

6. Programming and Software

Robotic welding cell programming demands precision. Ensure that the robot's path planning and programming are fine-tuned for accurate welds. Utilize welding software to optimize welding parameters.

7. Quality Assurance and Inspection

Implement quality checks within the cell, such as vision systems or sensors, to detect defects in real-time. This ensures defects are addressed promptly, reducing rework.

8. Maintenance and Serviceability

Design the cell with ease of maintenance in mind. Access to critical components, regular servicing schedules, and spare part availability are essential considerations.

Ready to embark on a journey of precision and efficiency with your robotic welding cells? Contact us today to schedule a consultation with our technical experts ⏭️ https://bit.ly/elite_meet

Let's collaborate to design welding cells that align perfectly with your manufacturing needs.

Share this post:

Sign up for blog updates!

Join my email list to receive updates and information.

Recent Posts

Sign up to receive the latest Automation & Robotics Trends

Grab a copy of our services

Contact Us

Elite Automation LLC

300 North Governor Street, Evansville, Indiana 47711, United States

Hours

24/7 - We support Emergency Service Calls

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.